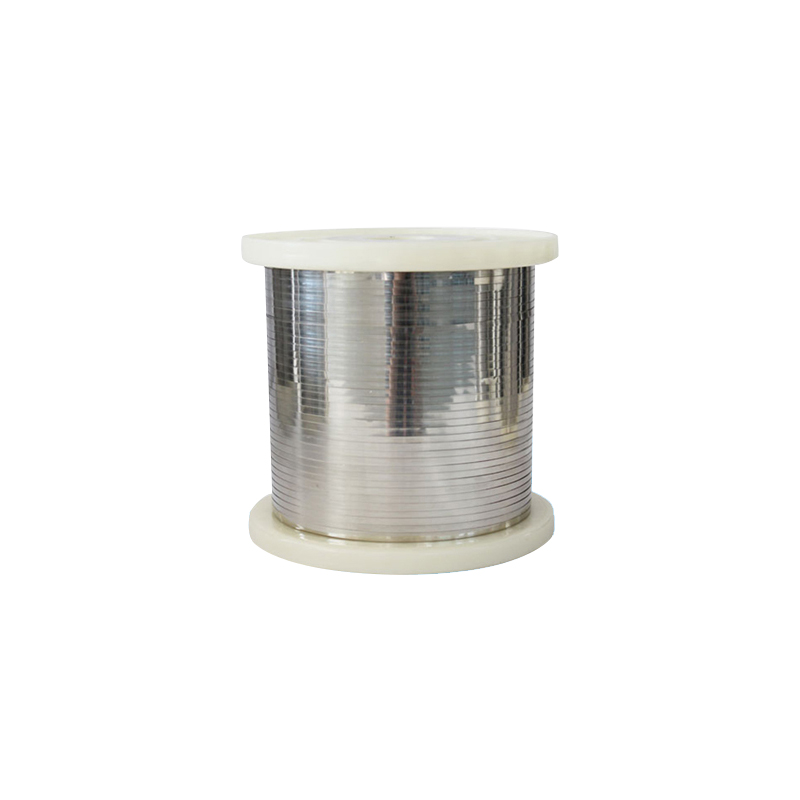

Reben fecral 0.2×2.5mm, Wayar Rata Pemanasan Rintangan 0cr23al5 dengan Sijil ISO9001

0cr23al5 Pemanasan Rintangan Wayar Rata dengan Sijil ISO9001

Wayar Rintangan diperbuat daripada Aloi Nikel Krom, Aloi Besi Nikel Krom, Aloi Aluminium Besi Krom, Aloi Nikel Kuprum.

Terutamanya digunakan dalam pemanas, elemen pemanas dan perintang, dsb.

NiCr 80/20, NiCr 70/30, NiCr 60/15, NiCr 35/20

FeCrAl15-5, FeCrAl20-5, FeCrAl 25-5, dan sebagainya…

Constantan, Aloi 30, Aloi 60, Aloi 90, dll.

Kerintangan Elektrik dari 0.02 u ohm/m-1.53 u ohm/m

Suhu Operasi dari 200 C hingga 1400 C

Sila hubungi kami jika ada sebarang pertanyaan.

NiCr:

RESISTOHM 20, RESISTOHM 30, RESISTOHM 40, RESISTOHM 60, RESISTOHM 70, RESISTOHM 80

FeCrAl:

RESISTOHM 125, RESISTOHM 135, RESISTOHM 140,

RESISTOHM 145, RESISTOHM 153

CuNi

Constantan, Cuprothal 5, Cuprothal 10, Cuprothal 15, Cuprothal 30, Eurica

| Gred Aloi FeCrAl | Komposisi Kimia % | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Re | Lain-lain |

| maksimum(≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | —- | 3.5-4.5 | 0.1 | Balas. |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | —- | 4.5-5.3 | 0.1 | Balas. |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | 0.1 | Balas. |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | 0.1 | Balas. |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | 0.1 | Balas. |

| 0Cr21Al4 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 21.0-23.0 | ≤0.60 | 3.0-5.2 | 0.1 | Balas. |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | 0.1 | Balas. |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | 0.1 | Balas. |

![]()

![]()

![]()

![]()

Komposisi dan Sifat Kimia:

| Hartanah/Gred | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Bahan Kimia Utama Komposisi (%) | Ni | Balas. | Balas. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Balas. | Balas. | Balas. | |

| Kerja Maksimum Suhu (ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Kerintangan pada 20ºC (μΩ · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Ketumpatan (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Kekonduksian Terma (KJ/m· h· ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Pekali Termal Pengembangan (α × 10-6/ºC) | 18 | 17 | 17 | 19 | 19 | |

| Takat Lebur (ºC) | 1400 | 1380 | 1390 | 1390 | 1390 | |

| Pemanjangan (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Struktur Mikrografik | austenit | austenit | austenit | austenit | austenit | |

| Sifat Magnetik | bukan magnet | bukan magnet | bukan magnet | bukan magnet | bukan magnet | |

![]()

![]()

![]()

![]()

| Gred Aloi CuNi | Kerintangan elektrik (20 darjahΩ mm² /m) | pekali suhu rintangan (10^6/darjah) | Ketumpatan g/mm² | Suhu maksimum (ijazah) | Takat lebur (ijazah) |

| CuNi1 | 0.03 | < 1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | < 1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | < 600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | < 570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | < 500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | < 380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | < 250 | 8.9 | 300 | 1135 |

| CuNi22 | 0.30 | < 160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | < 100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ± 40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.50 | < -6 | 8.9 | 400 | 1280 |

![]()

![]()

![]()

![]()

Kategori produk

-

Telefon

-

E-mel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Atas