Selamat datang ke laman web kami!

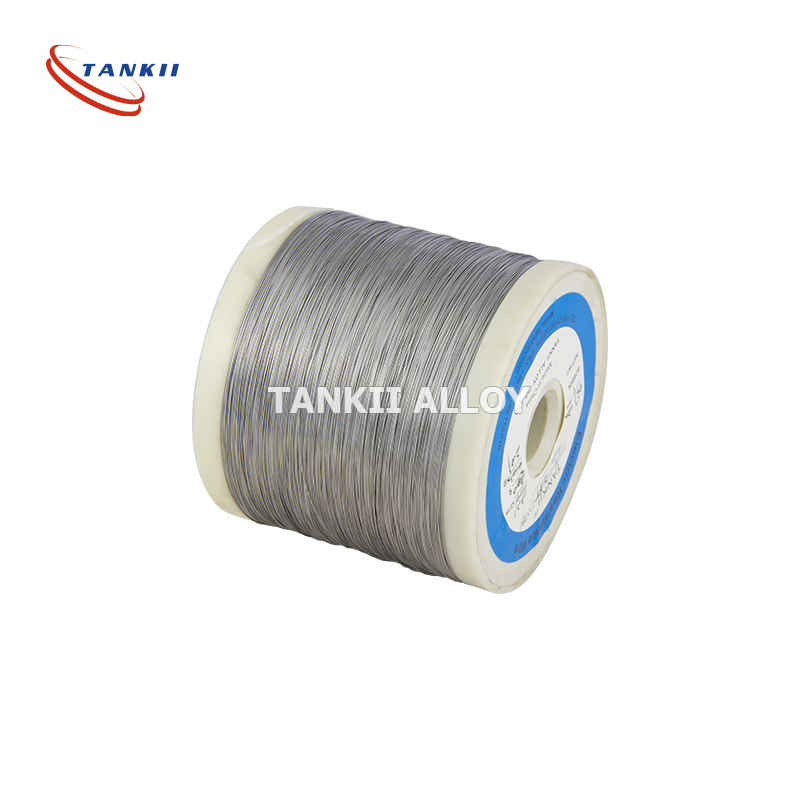

stok dawai rintangan ferroalloys OCr21Al6 0.14mm untuk dapur elektrik

stok dawai rintangan ferroalloys OCr21Al6 0.14mm untuk dapur elektrik

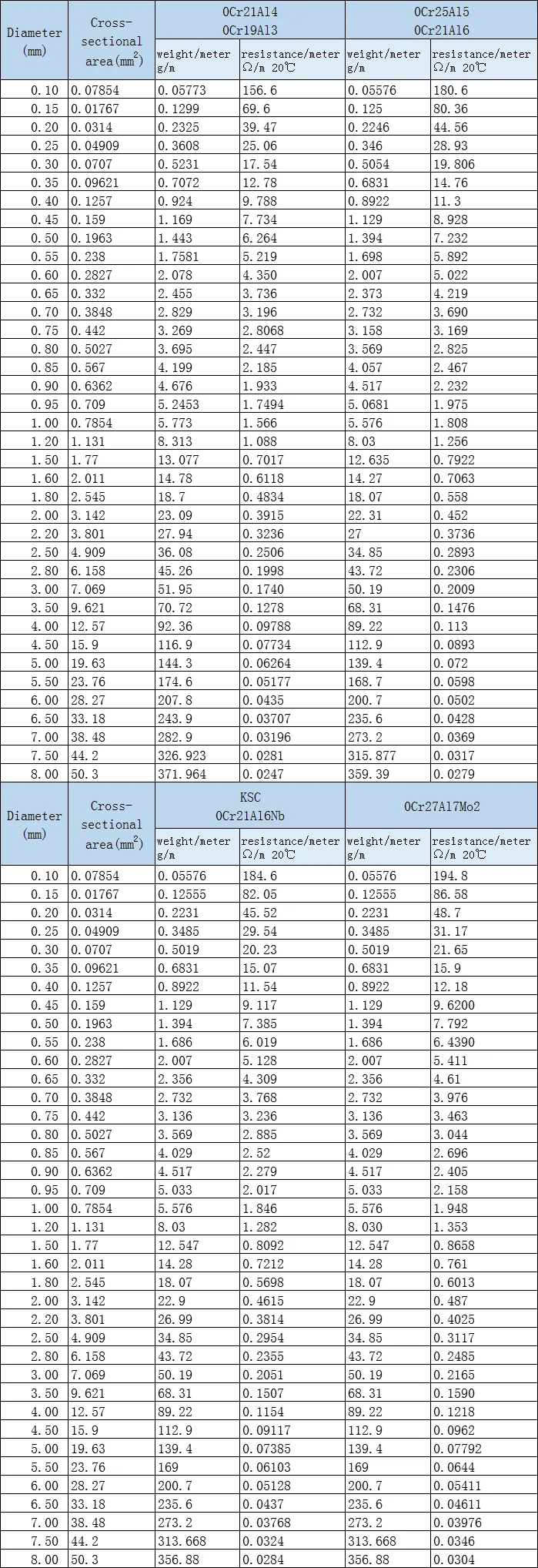

| Gred | 0Cr21Al6 |

| Saiz | 0.14mm |

| Permukaan | anil terang |

| Berat | 0.64kg/gulung |

| Kerintangan | 1.45±0.07μΩ.m |

| Suhu tertinggi | 1350℃ |

| Ketumpatan | 7.1g/cm³ |

| Kekuatan tegangan | 750N/mm² |

| Pemanjangan | ≥12% |

| Gred | Suhu tertinggi | Kerintangan | Takat lebur | Kekuatan tegangan | Pemanjangan |

| 0Cr21Al4 | 1100℃ | 1.23±0.06μΩ.m | 1500℃ | 750 | ≥12 |

| 0Cr25Al5 | 1250℃ | 1.42±0.07μΩ.m | 1500℃ | 750 | ≥12 |

| 0Cr23Al5 | 1300℃ | 1.35±0.06μΩ.m | 1500℃ | 750 | ≥12 |

| 0Cr21Al6NbCo | 1350℃ | 1.45±0.07μΩ.m | 1510℃ | 750 | ≥12 |

| 0Cr27Al7Mo2 | 1400℃ | 1.53±0.07μΩ.m | 1520℃ | 750 | ≥10 |

| KSC | 1350℃ | 1.44±0.05μΩ.m | 1510℃ | 750 | ≥16 |

| Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 1400℃ | 750 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 1390℃ | 750 | ≥20 |

| Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 1390℃ | 750 | ≥20 |

| Cr20Ni30 | 1100℃ | 1.04±0.05μΩ.m | 1390℃ | 750 | ≥20 |

| Gred | Komposisi kimia% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr21Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.0 | 17-21 | ≤0.6 | 3-4 | keseimbangan |

| 0Cr25Al5 | 0.06 | 0.025 | 0.02 | 0.5 | ≤0.6 | 23-26 | ≤0.6 | 4.5-6.5 | keseimbangan |

| 0Cr23Al5 | 0.06 | 0.025 | 0.02 | 0.5 | ≤0.6 | 20.5-23.5 | ≤0.6 | 4.2-5.3 | keseimbangan |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | keseimbangan |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.02 | 0.2 | ≤0.4 | 26.5-27.8 | ≤0.6 | 6-7 | keseimbangan |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | keseimbangan | <0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | keseimbangan |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | keseimbangan |

| Cr20Ni30 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 30-34 | - | keseimbangan |

Tulis mesej anda di sini dan hantarkannya kepada kami

Kategori produk

-

Telefon

-

E-mel

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Atas